Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

roll forming machine

William Zhou

Contact person

Basic Information

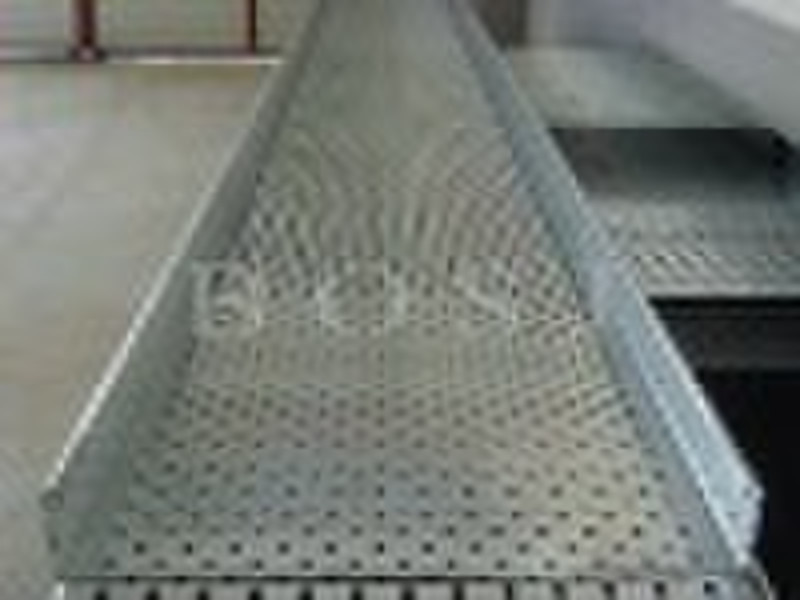

1, Equipment capabilities It can according to the need to produce the steel width (60mm≤§≤860mm), many kinds of specification electric cable bridges and other structure product.Product speed by punching: 2.55m/minContinuous rollforming speed: 1015m/minMaterial thickness: 1 2mmMaterial require: Q235 cold roll steelProduction line has automatic and manual two operating mode, may realize the linkage and the partition revolution work.2, Main composition of machineThis unit consists of the decoiler, ML-900 flatting, 200 punch, die, servo feeding, guider, main roll forming machine, follow cutting, cut-to-length part, recoiler, electrical control cabinet; etc.3,Each part major technical parameters3.1 Drive decoiler Material width860mmMaterial weight6000kgMaterial inner diameter460510mmMaterial outer diameter1200mmDrive power: electromotor and speed reducer integration, 4KW frequency conversion electromotor Frame type: cantalever inner support, manual handle afterbody, pneumatic press cantalever.3.2 FlattingWorking rolls: 11 rolls, up 4/down 5, the residual 2 rolls is clamp deliver rolls.Flatting bound: material thickness 12mm, material width 100860mmDrive power: 5.5kw frequency conversion electromotorSpeed reducer model: ZQ250flatting speed:310 m/minParenthesis up and down a pair of fortified wheel 3.3 Continual punching mouldAmount: Each kind of width specification 1 set dies, total 6 setsDie require: Cr12 quench3.4 Servo feeding set Servo electromotor power: 4.4kwMultistage type feeding, memory ten group of memory functions Man-machine contact surface numerical control system Uses Mitsubishi servometer3.5 Holds material (use in cushion section)The roller type, the both sides have the bearing support, 3 sets, use in holding the material and under the deposited material spacing.3.6 Guider A pair of horizontal roller and two pairs of vertical guide rolls, total 1 sets.3.7 Main roll forming machineType: GY180(Extra wide)Rack structure:Dragon Gate type memorial arch frameforming frame: 16 sets Forming variety: bridge framematerial max width:860mmmaterial max thickness:≤2.0mmforming width: 100600mmforming height: 50100mmThe diameter of the roller axis: 85mmRoll mould material: Gcr15,quenching treatment:HRC58-62°Drive type:30kw frequency conversion electromotor, ZQ500 Main speed reducerAutocephaly distribute gear case3.8 Hydraulic cuttingHydraulic pumping station: 5.5kwblade cuttimg, blade material Cr12, quench treatment3.9 Electrical control 3.9.1 Main operation control cubicleAmount: 1 setFrequency conversion: 3sets(in main control cubicle, control decoiler, flatting and roll forming machine)PLC control: 1 set8 inch liquid crystal touchscreens All electrical element is the Mitsubishi original installation brand3.9.2 Assistant control cubicleAmount: 3 sets (follow decoiler, flatting, roll forming machine)Control styp: manual handle4,Produce conditioncapability: about 71.5kwgas fountain: 0.9 cube/minProduction land area: 33m*3m

Delivery terms and packaging

Port: SHANGHAI

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: